SuperAA™ X5 Alpha-Amylase is a kind of thermostable α-amylase with high activity. It is derived from Bacillus licheniformis and produced through submerged fermentation and refining process. It can hydrolyse α- 1,4 glycosidic bond of starch randomly and reduces mash viscosity rapidly. SuperAA™ X5 Alpha-amylase is designed for starch-based feedstock ethanol production.

A cost-effective alpha amylase with very high activity from Bestzyme applied in ethanol industry which achieves complete starch conversion and ensures stable operation of liquefaction process

SuperAA™ X5 is a liquid enzyme containing outstanding thermostable α-amylase. This enzyme can hydrolyses α-1,4 glucosidic linkages of starch molecule to produce short dextrin chains, reducing viscosity of starch-based feedstock like cassava or corn quickly.

For ethanol producer, smooth running and high starch conversion rate are extremely important to achieve high ethanol yields. SuperAA™ X5 may become an ideal solution to meet your targets. The advantages are as follows:

Outstanding viscosity reduction performance

Easier liquefaction handling with wide pH and temperature range

Complete starch conversion to enhance ethanol yields

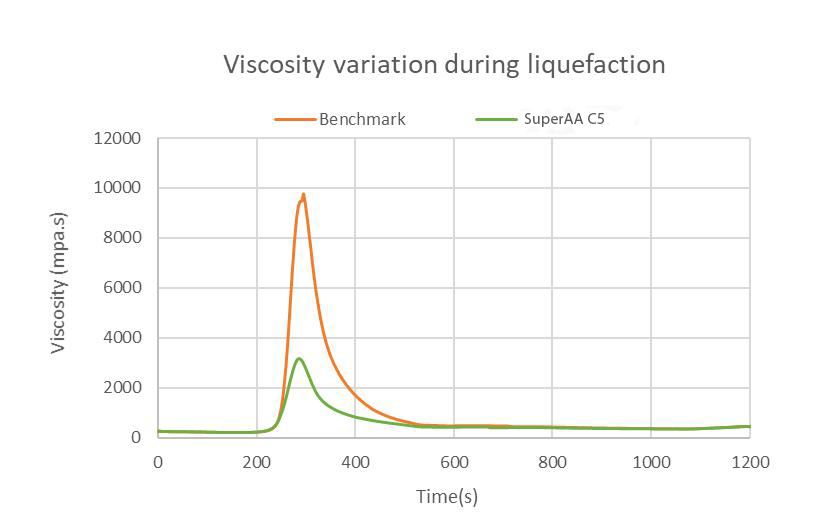

SuperAA™ X5 with high activity can provide the most cost-effective solution to help our customers decrease mash viscosity. High viscosity results in many problems in production. It's harmful to pumps, tank agitators, heat exchangers and jet cookers leading production fluctuation.

The starch must be gelatinized first to make sure the enzyme can bind to the substrate easily. The mash viscosity will reach to the peak during gelatinization which will cause serious problems if not handled properly. SuperAA™ X5 can help you decrease peak viscosity significantly compared to benchmark and enables high mash solids in liquefaction with no risk of system variation and save energy cost for plants.

SuperAA™ X5 is a kind of thermostable α-amylase and shows stable performance at wide pH range. That enables you to reduce the chemical consumption for pH adjusting before liquefaction and withstand production fluctuation to minimize the loss. What’s more, less chemicals also means better growing environment for yeast with less sodium which is beneficial to improve ethanol yield.

SuperAA™ X5 hydrolyze starch chain rapidly converting more starch to dextrins. The dextrins will be further broke down to smaller fermentable sugars in later saccharification together with fermentation (SSF). At the end of fermentation, there will be less residual starch in fermented mash because of high quality liquefaction. In a word, this product can boost liquefaction throughput and bring huge economic benefits.