LiqFINE BAA 1.0 is a thermostable amylase with high activity. It is derived from Bacillus licheniformis and produced through submerged fermentation and refining process. The consumption of chemicals and the impact on the environment can be minimized with the use of enzymes.

LiqFINE BAA 1.0 allows milder and more environmental friendly liquefaction process. The viscosity of starch slurry decreases rapidly because of the high reaction rate, yielding short chain dextrins and a little oligosaccharides. It can be used to achieve high dextrose yields. with saccharification enzymes. LiqFINE BAA 1.0 can be applied in liquefaction process based on starchy materials within starch sweetener and fermentation industries (e.g.amino acid, citrin).

LiqFINE BAA 1.0 provides the following benefits:

The jet cooker temperature can be increased to 120℃ with high residual enzyme activity because of unparalleled heat resistance feature.

Excellent low-pH tolerance and stable performance from pH 4.8-5.8.

Boosting DX levels by 0.3% points.

Increasing fermentation yields with more fermentable sugars.

Less chemical consumption and waste water generation.

Less energy and water costs.

Less calcium reliance and no extra addition of calcium using tap water.

The LiqFINE BAA 1.0 performance depends on dry substance, pH, jet cooker temperature and laminar flow time, etc.

Recommended application conditions

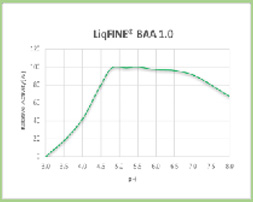

Fig 1 The pH profile of LiqFINE BAA 1.0

LiqFINE BAA 1.0 shows stable performance at pH range from 4.8 to 5.8. To achieve best liquefaction effect, adjusting pH at 5.0-5.6 is a good choice(Shown in Figure 1).

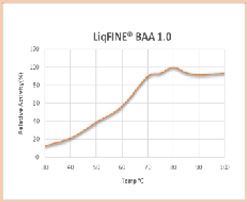

Fig 2 The temperature profile of LiqFINE BAA 1.0

LiqFINE BAA 1.0 has the greatest thermostable characteristic (Residue activity under 100℃ is above 90%, shown in Figure 2) and shows outstanding liquefaction performance even the temperature of jet cooker increased to 120℃ under the substrate protection.