FastLIQ STAR150 Alpha-Amylase is a kind of thermostable amylase with high activity. It is derived from Bacillus licheniformis and produced through submerged fermentation and refining process. FastLIQ STAR150 Alpha-amylase can hydrolyse α- 1,4 glycosidic bond randomly. The viscosity of starch slurry decreases rapidly because of the high reaction rate and this process is called liquefaction yielding short chain dextrins and a little oligosaccharides. FastLIQ STAR150 Alpha-amylase can be applied in liquefaction process based on starchy materials for starch sweetener and fermentation industry (e.g., amino acid, citrin).

An innovative cost-effective α-amylase from Bestzyme applied in starch & sweetener industry ensuring stable operation of starch liquefaction and saving manufacturing cost

FastLIQ STAR150 is a high efficient thermostable alpha amylase that hydrolyses alpha bonds of large, alpha-linked polysaccharides yielding dextrin chains at wide pH range and high starch slurry concentration condition.

For starch & sweetener producer, smooth running of jet cooker and increasing operation efficiency in starch liquefaction are extremely important. FastLIQ STAR150 provides superior and industry-proven performance to ensure liquefaction effect bringing economic benefits to our customers.

High starch hydrolyses rate with low dosage

Rapidly viscosity reduction makes high starch slurry operation possible. Therefore increase efficiency

Reduce the consumption of chemicals and lighten the load of ion exchange column

Reduce the pressure of filtration system

FastLIQ STAR150 with high activity can provide the most cost-effective solutions to help our customers decrease the variable cost.

Except the high capability of starch hydrolysis, the FastLIQ STAR150 can reduce the viscosity of starch slurry which is extremely vital for production process.

Reducing viscosity rapidly can ensure the stable operation of jet cooker (if the viscosity of starch slurry is too high, the jet cooker will shake violently resulting in failure of starch liquefaction)

Increase on-line time of filtration system and reduce the consumption of filter-bag, filter aid etc.

Reduce the consumption of chemicals at low pH condition using FastLIQ STAR150

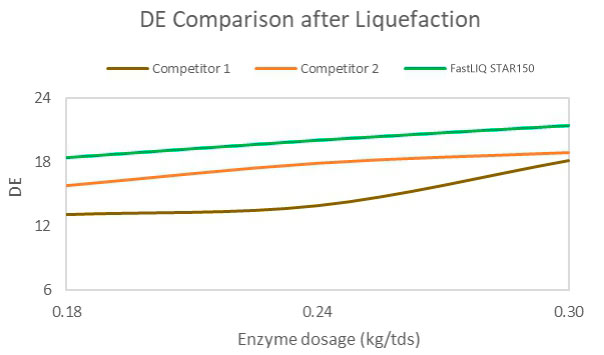

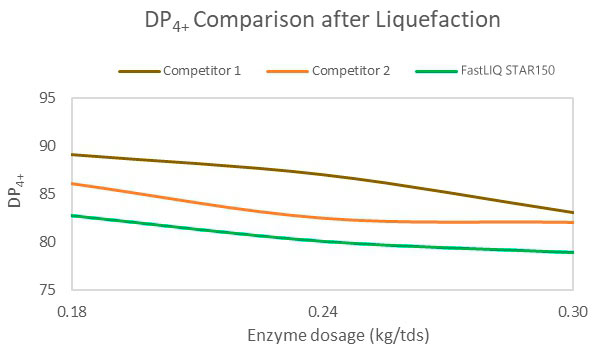

Better liquefaction effect with higher DE and lower DP4+ content at same condition

The content of reducing sugar (DE) and long starch chain (DP4+) can be regarded as index to evaluate the effect of liquefaction. Higher DE and lower DP4+ in the same reaction condition means better capability of starch hydrolyzation level and faster rate of viscosity reduction.

The dosage of FastLIQ STAR150 can be decreased to achieve same starch liquefaction degree compared to competitors’ products. FastLIQ STAR150 provides a better economic saving solution to customers

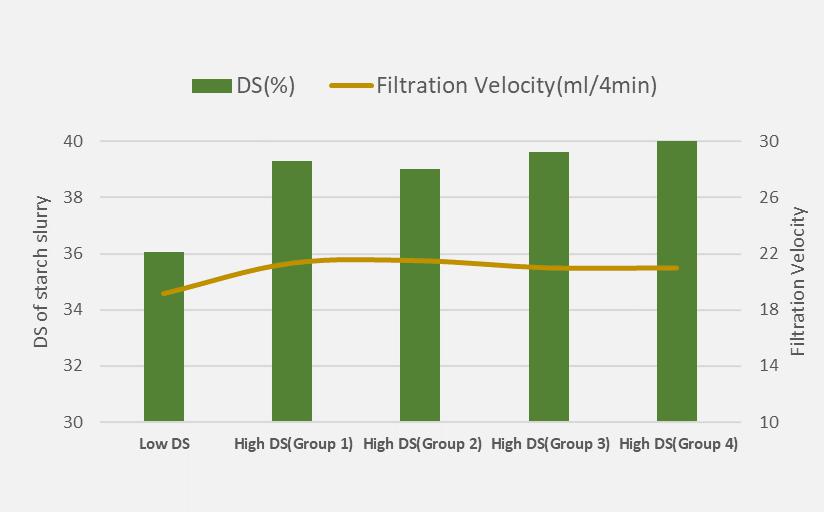

FastLIQ STAR150 has demonstrated stable and trustworthy performance in plant. The DS (dry substance) of starch slurry can be increased from 36% to 40% using FastLIQ STAR150 in starch liquefaction process. Accordingly, the production efficiency rise greatly.

This figure shows that even increase starch slurry DS from 36% to 40%, the filtration velocity is still around the same level of the low DS operation demonstrating excellent viscosity reduction effect of FastLIQ STAR150.

To achieve same liquefaction level, the dosage of FastLIQ STAR150 was 10% lower than competitor and pH was decreased from 5.6 to 5.2. Because of less chemical addition to adjust pH in liquefaction, the syrup conductivity was also decreased accordingly. Lower conductivity can lighten the load of ion removal and prolong the online time of ion exchange column.

FastLIQ STAR150 showed excellent performance both in application research lab and plant of starch & sweetener industry and it also has promising potential at even harsh process condition.